That said, judicious choices made when orienting the part, can certainly help achieve the desired level of detail. While FDM models are known for being dimensionally accurate, when working with intricate detail (close to the 0.254mm dimensional limit), it is possible to run into problems. These are 0.254 mm in diameter and this dimension not only defines the layer thickness during the build process, but also has an effect on the resolution. Inside each material bay the ABS and support material are held in reels of filament, which are fed directly into the nozzle.

#Catalyst ex download stratasys software#

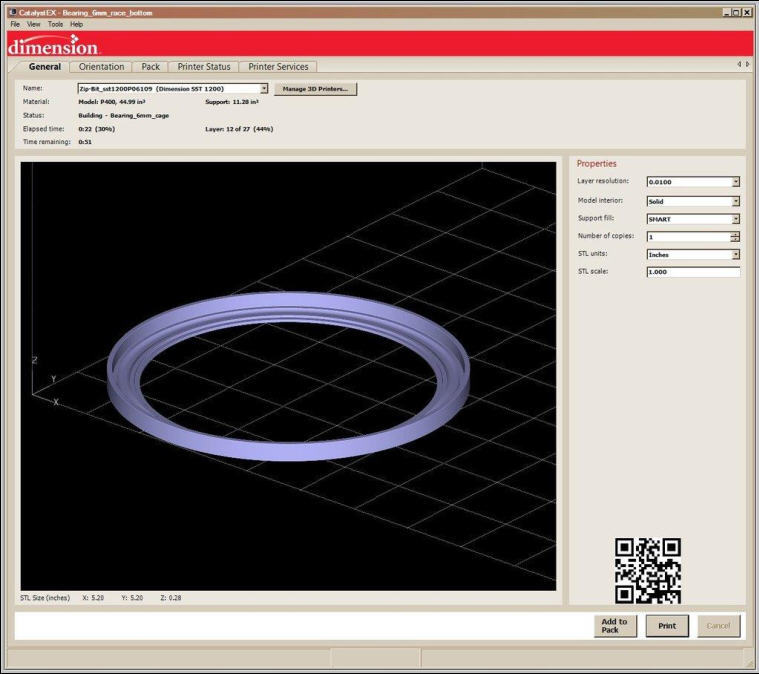

The system comes with Catalyst EX software which offers all you need for model preparation, from machine admin and control, through STL data import, orientation and scaling tools to prepare each build job. Once it’s assembled, you connect the machine via Ethernet and get the software up and running. The material bay sits underneath the printer and can be doubled up to offer longer periods of unattended model building. The machine comes into two core parts: the printer itself and the material bay.

Higher resolution will mean much less faceting in the final model The part in SolidWorks – an STL file is exported to the required resolution. Everything is clearly labelled and there’s even a quick reference guide. Installation is very similar to that of a traditional printer. I would hazard a guess that this is about as small as these things are going to get considering it sports a very usable 203 x 152 x 152 mm build envelope.

The uPrint is a very small form factor machine and it sits easily on an office desk. So, there’s the background, now let’s looks at the specifics of the uPrint machine, which Dimension is touting as a personal 3D printer. Parts are more resilient, suitable for form, fit and function testing and generally stand up well to the rigours of life as a prototype part. By using near molten material (typically ABS but others are available in the higher-end systems), the technology gives users a very good approximation of product-intent material. The benefit that FDM has traditionally held over its competitors is the superior structural integrity of the parts.

This support material is then removed (it’s water soluble) and hey presto, there’s a 3D model, realised as a physical 3D part. In most FDM machines the system also deposits a support material to assist with maintaining form within the model during the building process and to allow users to build complex parts in the required orientation. Print directly from CAD, organize print queues, monitor material levels and work with detailed views of your model.FDM models are renowned for their toughness and accuracy making them suitable for physical testing GrabCAD Print simplifies the traditional 3D print preparation workflow and provides intelligence around printer usage so your team can get quality prints, faster. GrabCAD Print™ software (site license) and/or CatalystEX™ software (site license).

#Catalyst ex download stratasys plus#

UPrint SE Plus and two material bays: 635 (w) x 660 (d) x 940 (h) mm (25 x 26 x 37 in) 94 kg (206 lbs)ġ00–127 VAC 50/60 Hz, minimum 15A dedicated circuit or 220–240 VAC 50/60Hz, minimum 7A dedicated circuit UPrint SE Plus and one material bay: 635 (w) x 660 (d) x 787 (h) mm (25 x 26 x 31 in) 76 kg (168 lbs) ABSplus in ivory, white, blue, fluorescent yellow, black, red, nectarine, olive green, gray

0 kommentar(er)

0 kommentar(er)